With years of experience developing polishing wheels for drill flutes, turbine blades, cutlery and medical devices, now åtto manufactures a range of Diamond Polishing wheels for Tungsten Carbide and Hardmetals.

Designed for use on a wide range of machines and applications. For Carbide tools, the åtto wheel is suitable for use on CNC machines in conjunction with your current flute grinding setup.

An åtto superfinished Carbide tool, has significantly improved tool life and higher cutting speeds.

The åtto diamond range is suitable for use on metal spray coatings, PCDs, Ceramics and for super finishing rolls.

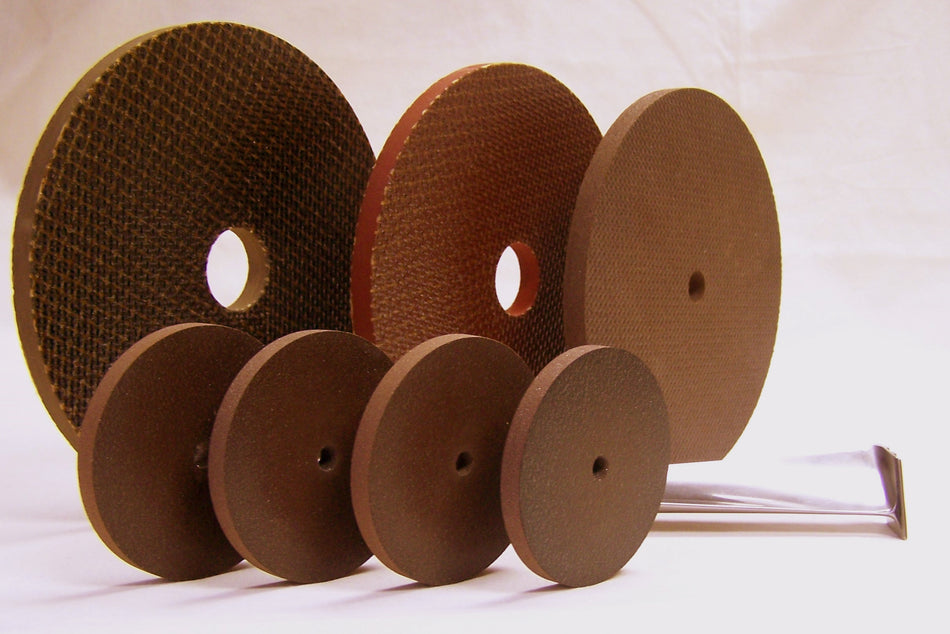

Range:

- Diameters: 75 to 200 mm ( 3” to 8”)

- Thickness: 3 to 50 mm ( 1/8” to 2”)

- Bores: as required

- Additional sizes upon request

Highlights:

- Elastic Bond

- High concentration of quality diamond

- Longer wheel life

- Outstanding Surface Finish

- Extensive range of sizes

Advantages:

- Conforms to the flute

- Polishes all surfaces

- Outstanding surface finish for better results

- Reduced costs

Case Study:

Carbide End-mill Polishing Results:

Application: Polishing flute core and rake angle Carbide end-mill

Machine: Walter Vision – 12 tool holders

Coolant: Oil (Pump 50 bar/ Nozzle 12 to 15 bar)

M.O.S.: 35 m/sec

Wheel Size: 150 x 10 x 20 mm

Carbide End-mill: 20mmØ 4 flute

Material: Carbide

åtto specification: DC8002-S3-KF711

Time: 80 sec per operation

Traverse: 120mm/min

Finish Achieved: Workpiece optically checked

Finish: Mirror

For more information or to discuss your specific requirements:

Contact åtto Abrasives at atto@attoabrasives.com