2 Products

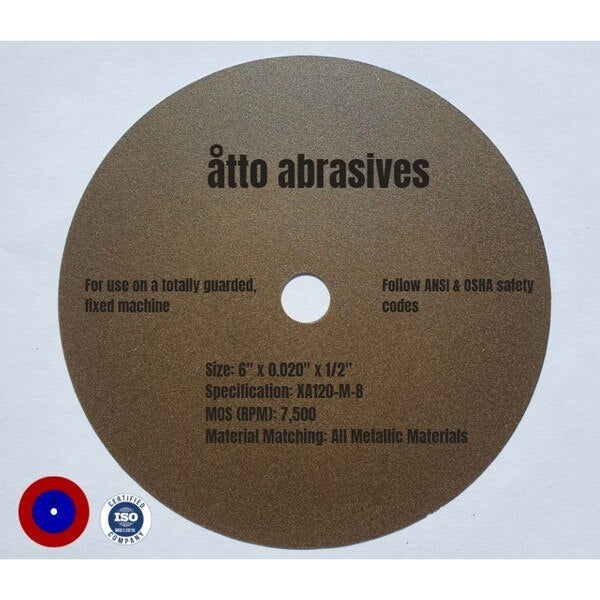

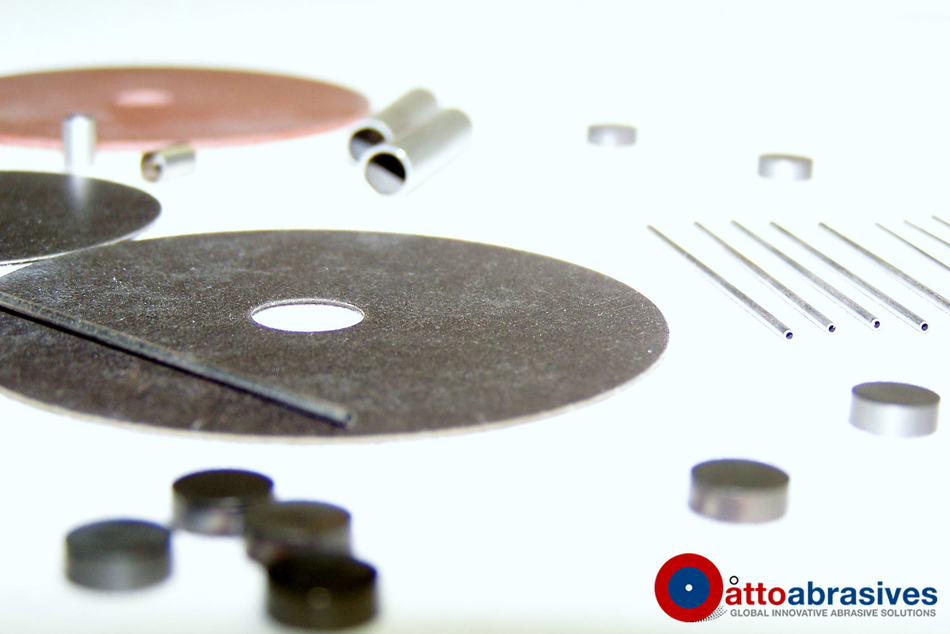

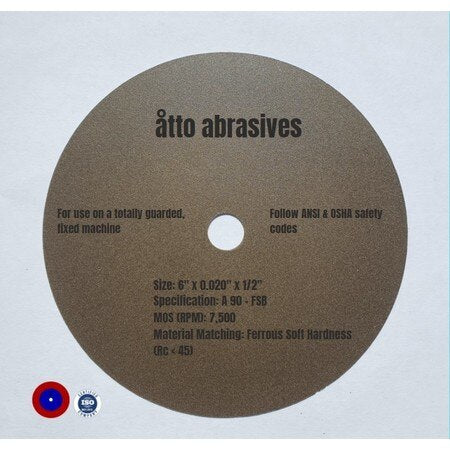

Collection: Resin cutting discs

Resin Bonded Precision Cutting Discs

Are most suitable for precision cutting applications. These include the precision dry cutting of: medical tubes, hypodermic needles, metallurgical sampling and other applications. They are also suitable for wet cutting applications.

Benefits include

- Cost-Effective Cutting

- Faster operation

- Minimum Heating

- Maximum Reduction of Burr

- Improved Efficiency

The Resin bond holds the wheels’ abrasive components (e.g. Aluminium Oxide, Silicon Carbide etc) together and allows the wheel to wear away at a specific rate, releasing the abrasive particles for the cutting action.

Thanks to our diligent production staff, åtto can produce cutting wheels to a thickness of 0.1mm at a tolerance of +/-0.025mm.